3-Strand Rope Repair | Loop eye splice

Repairing the loop end of a 3-Strand Nylon-66 kinetic recovery rope is rare. This would generally only be needed in situations where there has been heavy abrasion. Regardless of the cause this is an easy repair to do and can be done in the field. You can do this with with no tools but after mid to full loaded recoveries the strands will be a lot tighter together requiring some leverage getting them to loosen up. The tidier you make the job the better the loop will hold and done correctly you will have a 100% non-slip loop.

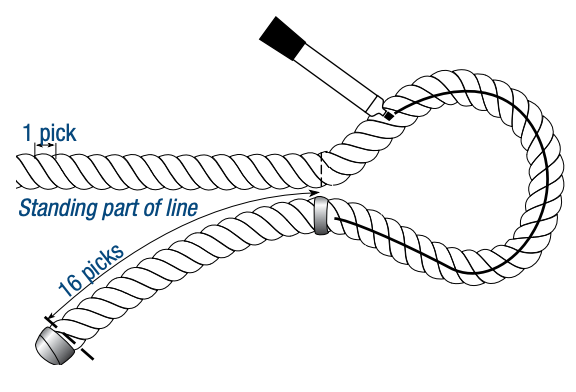

First off | From one end of the rope count back 16 picks then tape this section. Unlay the rope up to the tape end of the stand from the eye and mark a line around the standing part of the rope that will touch all 3 strands. Your individual taped strands will tuck under these marks. Draw a line on the eye for easy reference.

Step 1: Tucking in the first stand

The mark around the standing part of the rope that touches all 3 strands is where your individual taped stands will tuck under. Tuck the middle stand (stand 1) under the nearest marked pick. This is probably the most difficult part of the whole job.